The electrical generation sector is facing a future of disruptive changes with the implementation of more renewable energy, a higher demand of electricity due to more electric transport and newly developed storage technology.

Power plant digita…

WE BRING YOU:

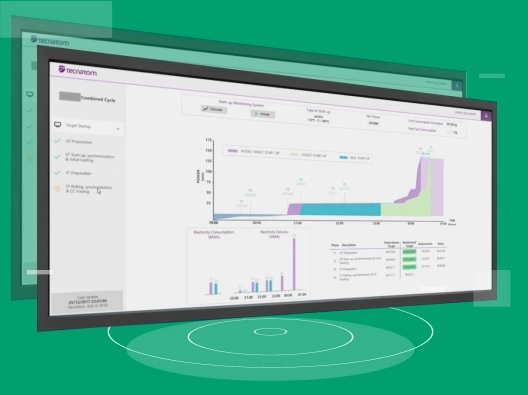

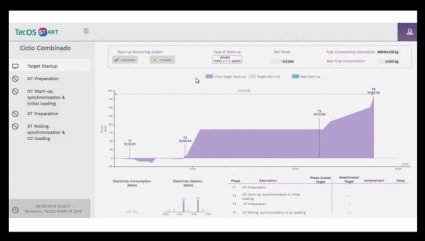

TecOS START allows for the optimization of the start-up process (time, fuel consumption and power generation) of the power plants by using machine learning.

Benefits

TIME AND COST SAVINGS

This solution makes accurate predictions (based on machine learning) of start-up time and cost, considering current plant conditions as it basis.

AVOIDANCE OF PENALTIES

This tool enables the tracking of deviations so necessary corrections can be made in advance in order to avoid penalties.

START-UP PROCESS OPTIMIZATION

The information provided by the system allows for the optimization of the power plants start-up process, improve process planification and early detection of deviations.

DATA ANALYSIS

Improve time, fuel consumption and power generation estimations during the start-up process of the power plant, taking informed decisions.

TecOS START features

Analyzes and optimizes your power plant’s start-up process.

- Early detection of deviations.

- Find out fuel consumption during start-up.

- Reduce consumption of fuel and auxiliaries during start-up.

Detailed and accurate start-up planning

- Plan your start-ups, obtaining real estimates for time and cost.

- Supervise critical processes.

- Receive alerts that have been configured for your plant.

Up to 5000€ reduction of fuel consumption during a start-up process.

Find out your hypothetical savings.

· NEED TO KNOW MORE?

What can you do?

Suite’s solution that allows for optimization of the start-up process of power plants that have frequent starts and stops, reducing the process costs and, thus, improving the facility’s financial performance.

By applying machine learning algorithms, TecOS START yields precise estimates of start-up time, consumption of gas and auxiliaries, and energy generation throughout the entire start-up process.

Find out the start-up time required for your power plant based upon its initial conditions for improving your tasks planification, thus reducing fuel consumption and avoiding penalties.

The analysis of the data generated through TecOS START allows users to study the start-up process and detect the different actions that can be taken to improve and optimize said process.

The application of machine learning algorithms to your process provides accurate estimates of the amount of time required for the process. TecOS START adapts based upon your plant’s historical data, allowing for estimates to be improved and tailored.

Supervise the critical parameters that come into play during plant start-up and receive alerts if they undergo significant deviations. All of this information is provided to staff by means of high-performance displays that have been designed with the highest human factors engineering standards in mind.

How does it work?

TecOS START is the TecOS Suite's solution for predicting and monitoring your plant's start-up. With the help of TecOS START, you will be able to supervise key parameters and your plant will get connected to the grid on time and with the lowest possible cost.

1.

Start-up Planning

Improve the tasks planning thanks to the estimates provided by TecOS START. This, in turn, improves efficiency and cuts down on fuel use during the plant’s start-up process.

2.

Optimization of Start-up

By analyzing the data generated, the evolution of critical parameters is identified during the different start-ups, allowing processes to be studied and optimized.

FAQs

Yes, TecOS START can be used in combined-cycle plants with any type of technology.

Yes, TecOS START is tailored to each and every plant and it adapts to operational procedures and processes. The machine learning algorithms are adaptable to each plant features and are trained in each start-up process of your plant.

Yes, during the implementation phase, Tecnatom trains plant staff so that they can easily use the tool during start-ups.

The deployment of TecOS PROCEED can be adapted to the specific customers’ needs, including network architecture and cyber security constrains.Users with permissions can view start-up processes on any connected device through an internet browser.

This product is transferable to other steam power plants technologies that suffer from high-cycling start-ups.

Blog News

Our world is changing at an unprecedented speed, involving challenges such as the population growth, the environmental degradation and the economic re…

The digital copy that enhances and improves the performance of the reality being replicated.

The term "digital twin" seems to be a magic concept in th…

The power generation industry is currently facing the need to reduce operating costs while maintaining the safety and availability of power plants. Co…