The electrical generation sector is facing a future of disruptive changes with the implementation of more renewable energy, a higher demand of electricity due to more electric transport and newly developed storage technology.

Power plant digita…

WE BRING YOU:

TecOS SOLCEP

Online performance monitoring system

On-line monitoring of the plant performance to identify, allocate and monetize the performance losses. It is a useful tool for the plant personnel to diagnose equipment and system malfunctions related to thermal efficiency and optimize the operating strategy.

Benefits

FROM EXPERT TO CLIENT

Experts in process, performance, operation, maintenance and engineering with the latest technology .

ADAPTABLE TO CLIENT NEEDS

Performance online monitoring services are offered from Tecnatom’s monitoring centre, in addition to regular reports, recommendations and on-demand assistance. Adaptable tool to any facility technology. Specific models for each plant (Digital Twin).

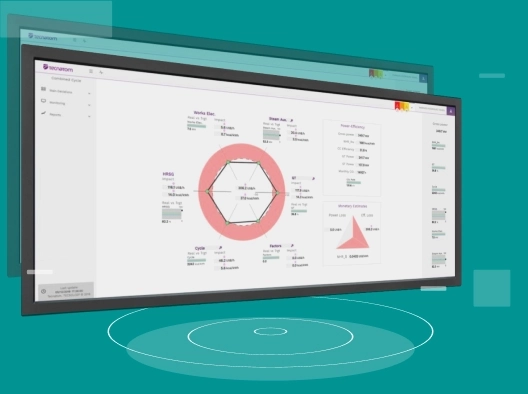

SMART INTERFACE

Information is shown intelligently through human factors engineering implementation, offering a quick insight into any possible deviations while facilitating the decision-making process. Information accessible from anywhere.

IDENTIFICATION OF PLANT OPERATION ANOMALIES

Assisted diagnostic for identification and understanding of the events taking place within the plant. Directed by expert knowledge and data science .

INCREASING PLANT PRODUCTION

On-line remote monitoring. Plant operation optimisation. Identifying, allocating and monetizing the performance losses.

OPERATION AND MAINTENANCE COST REDUCTION

Supporting decision-making on operation and maintenance strategies to maximize the company’s results. Monitoring key equipment and its parameters.

TecOS SOLCEP features

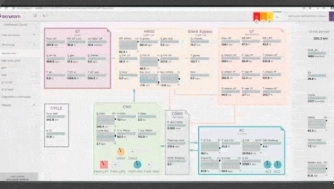

Identification and monetization

- Identifies, allocates and monetizes the plant's performance-based losses.

- Quantifies the performance losses of the plant in accordance to plant instrumentation and thermohydraulic balances, estimating any non-instrumented variables.

- Based on the ASME PTC guides and more than 60 years of experience.

Monitoring services

- Tool calculates for every parameter, component and system the deviation between the real and the objective value and quantifies this deviation in terms of production and cost.

- All information is provided to support users decision making on O&M strategies and to maximize the company's results.

- Tecnatom provides services to support the performance monitoring carried out by our operation, maintenance and performance experts from our monitoring centre.

Want to know more about TecOS SOLCEP?

Check the TecOS SOLCEP Webinar were you can learn the last features and capacities developed by our team.

·ACCESS TO WEBINAR

What can you do?

TecOS SOLCEP enables many other operations to be carried out, in addition to online monitoring plant performance. These are made up mainly by:

Helps the user to identify any anomaly in the plant components or systems. This module contains all the experience gained by Tecnatom over the last 60 years in power plant processes and operations, thermohydraulics and asset management.

All the module interfaces follow the outset of TecOS SUPERVISE, a smart interface based on human factors engineering, with the aim of improving user performance and supporting decision-making.

How does it work?

TecOS SOLCEP is the TecOS solution that will improve the Performance and Optimize the operation of the plant while saving money. It can be deployed on cloud or on-premise-

1.

Smart Interface

TecOS SOLCEP interface is based on another TecOS solution: TecOS SUPERVISE

This high level interface aims to help the users to improve their performance through pattern recognition and the smart integration of information.

2.

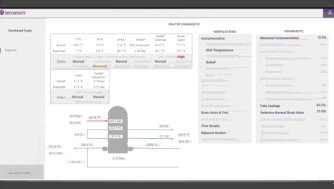

Assisted Diagnostic Module

Assisted diagnostic allows the operator to identify the malfunction or degradation that is taken place in plant.

When faced with a malfunction or degradation, «diagnostic» column will show the possible causes while «verification» column will show the actions that need to be taken by the operator to limit the problem, with the overall aim of producing a quick and clear diagnostic.

3.

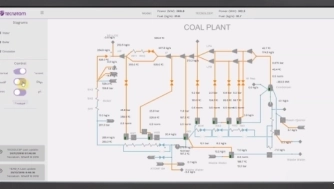

What-if Module

What-if module is a stationary simulator with the objective of optimising the plant objectives. User must select the data entry for What-if: current or historical, design data. Then, operator may carry out different manoeuvres in order to increase production with the same fuel or use less fuel to obtain same power leve.

l Some of these manoeuvres are:

– Modifying fuel composition or environmental conditions

– Using degradated components

– Modifying control setpoints

FAQs

No, the TecOS SOLCEP modules can be acquired independently.

Performance monitoring of the plant and its equipment, the identification and quantification of deviation causes, and recommendations to counteract them. Status monitoring and coherence of the instrumentation values. Decision-making support for the optimisation of the operation. Decision-making support for maintenance and/or equipment replacement work.

The TecOS SOLCEP deployment requires a software server that is connected to the plant’s Data Server. The data can then be transferred to our monitoring centre through a secure VPN connection, where all the plants’ performances are monitored. If the user does not require monitoring services, there is no need for a VPN.

Yes, tool models are adapted to plant technology, processes and current instrumentation.

Yes, specific training is given to the users and system administrators.

Yes, from anywhere and with any of the company’s intranet devices, as well as from any location that has a secure fixed/mobile router internet access connection.

Blog News

Our world is changing at an unprecedented speed, involving challenges such as the population growth, the environmental degradation and the economic re…

The digital copy that enhances and improves the performance of the reality being replicated.

The term "digital twin" seems to be a magic concept in th…

The power generation industry is currently facing the need to reduce operating costs while maintaining the safety and availability of power plants. Co…