The electrical generation sector is facing a future of disruptive changes with the implementation of more renewable energy, a higher demand of electricity due to more electric transport and newly developed storage technology.

Power plant digita…

WE BRING YOU:

Systematic approach to planning, scheduling, executing, monitoring, updating, evaluating and predicting inspection needs. It integrates all relevant analysis, current and historical inspection data and standards into an homogenous tool for managing efficiently the inspections, enhancing the analysis, making smart decision making and reducing the inspection costs.

Benefits

INTEGRATED INSPECTION MANAGEMENT

– Fast access to current and historical data.

– Critical information is easily understood.

OPTIMIZED INSPECTIONS AND OUTAGES

– Decision making tool based on the analysis of previous results data.

– Inspection progress follow-up to detect deviations.

INSPECTION SCOPE PROGRAMMING

– User-friendly interface for inspection programming.

– Inspection progress follow-up to detect deviations.

INSPECTION REPORTS

– Information displayed in the right format to assist decision makers.

– Embedded pictures and documents.

TecOS GIPE features

Efficent inspections management

- Automatic inspection plan.

- Gantt diagram inpection management.

- Inspection reports.

Enhanced analysis and decision making

- All inspections data displayed in the right format to assist decision makers.

- Useful life evaluation based on thermal fluency and fatigue. Proposal of inspection schedule based on remnant life.

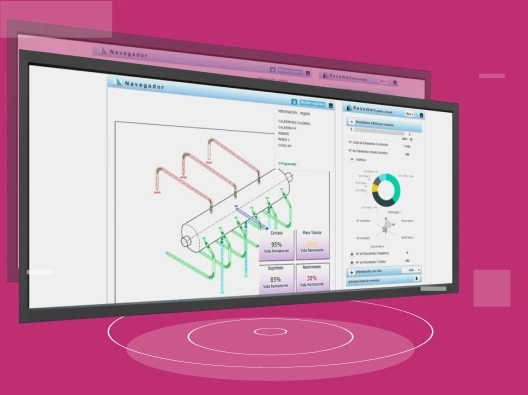

- Graphical Representation of inspection scope and results. Report and Dashboard.

Reduce inspection costs

- Inspection manual update and inspection plan based on all the information analysis.

- Automatic data storage.

What can you do?

User-friendly interface

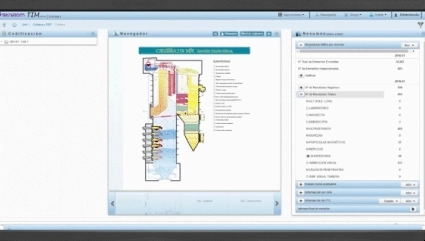

– Graphical representation of inspection areas showing inspection scope and results .

– Inspection techniques specific modules .

– Dashboard to represent results.

Data Storage and Report Builder

– Inspection sheets generated by the tool.

– Automatic Data Storage.

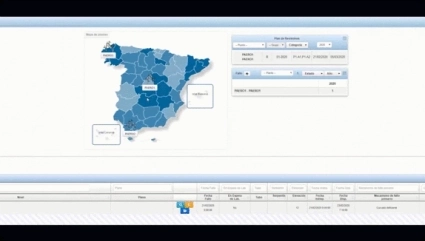

– Integrates all fleet inspections data.

– Generate and stores reports.

Project Planning and Inspection plan tracking

– Based on inspection plan program, automatic Gantt diagram generation to survey, manage and optimize the inspection process .

– Tracking of inspection progress by each task .

– Information analysis to optimize future inspections.

How does it work?

TecOS GIPE provides a systematic approach and integrates all inspection and testing needs.

1.

GIPE Execution

TecOS GIPE may be used in industries where inspections are programmed, planned and executed. It warranties the accomplishment with applied regulations and supports the efficient decision making to optimize the overall inspection costs. TecOS GIPE may be used in power plants (coal, gas, renewable), Oil&Gas, industrial.

2.

GIPE Users

TecOS GIPE main users are inspection programmers, maintenance managers, fleet outage managers and, inspection data analysts.

FAQs

Yes, all the existing data on the inspections can be integrated in the system so we can analyze the information for our best decision making.

Tecnatom can build the inspection manual for your plant/industry so you can take advantage of this tool benefits.

TecOS GIPE supports all the main inspection techniques.

Blog News

Our world is changing at an unprecedented speed, involving challenges such as the population growth, the environmental degradation and the economic re…

The digital copy that enhances and improves the performance of the reality being replicated.

The term "digital twin" seems to be a magic concept in th…

The power generation industry is currently facing the need to reduce operating costs while maintaining the safety and availability of power plants. Co…