The electrical generation sector is facing a future of disruptive changes with the implementation of more renewable energy, a higher demand of electricity due to more electric transport and newly developed storage technology.

Power plant digita…

WE BRING YOU:

TecOS ALERT reduces the number of alarms shown to the operator thanks to data science techniques.

Benefits

AVOID AN AVALANCHE OF ALARMS

In accordance with EPRI recommendations for control rooms of power generation plants, the number of alarm activations should be less than 150 per day (6 alarm activations / hour).

ERROR REDUCTION

The likelihood of errors during operation is reduced. A reduction in the number of alarms reported reduces the risk that said alarms are not correctly dealt by staff, avoiding incidents and accidents.

NO DCS MODIFICATIONS

TecOS ALERT executes on a layer above the DCS; therefore, no DCS configuration changes are necessary.

REDUCTION OF THE OPERATOR’S COGNITIVE LOAD

Only alarms that require operator action will be notified.

DATA SCIENCE

TecOS ALERT combines machine learning algorithms with expert knowledge for smart alarm management.

EFFICIENT ALARM MANAGEMENT

TecOS ALERT provides a great value with relatively lower costs and short implementation periods compared with traditional approaches (an engineer analyzing alarm logics).

TecOS ALERT features

Definition of alarms / Analysis amd review of alarm logics.

- Remove alarms that should not be enabled (amd).

- Avoid continuous activations and deactivations of the same alarm: adjust setpoints.

- Assign to each alarm the required priority level, taking into account severity and proper definition in accordance with consequences.

- Electronic alarm book generation.

Prioritization and filtering.

- Support the operator providing information to prevent avalanches of alarms during transient events and improving problem diagnosis.

- Dynamic prioritization: based on operating modes and plant events.

Smart alarm management.

- Take advantage of the tools provided by data science and expert knowledge to reduce the number of alarms reported.

- Ensure that the information shown on the alarm interface is the only information that must be handled by operators.

- A great value with relatively low costs and short implementation periods compared with traditional approaches (an engineer analyzing alarm logics).

Real scenario data

Case study conducted at a control center for hydraulic power plants

30 MILLIONS

Generated alarms

15-20%

Notified alarms

80-85%

Eliminated alarms

Discover your hypothetical savings

Let us show you how TecOS ALERT can help YOUR BUSINESS. See which are the savings and benefits that you could have using the solution.

· NEED TO KNOW MORE

What can you do?

The aim of the alarm management solution is to ensure that the information shown on the alarm interface is the only information that must be handled by the operators. Alarms that do not require corrective action, do not inform of an abnormal situation, and/or supply redundant information should not exist.<br>

TecOS ALERT can be connected to the plant’s DCS.

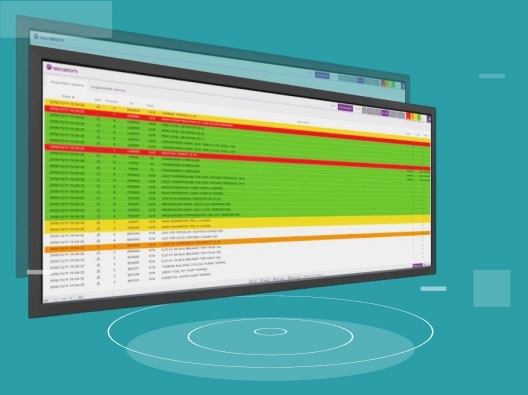

TecOS ALERT is executed on a layer above the plant’s DCS or SCADA, communicating with it in order to read the alarms generated.

TecOS ALERT notifies the important alarms on a different screen of the DCS one.

The implementation of TecOS ALERT consists of:

– Training with alarm history.

– Offline validation.

– Installation, validation and adjustment at the plant.

How does it work?

TecOS ALERT is an automatic, dynamic alarm rationalization tool that uses data science techniques and automated learning, as well as knowledge from operation and I&C experts. The performance of TecOS ALERT is based on a modeling of the alarm system behavior during the training phase. The predictive power of the models allows the system to decide what alarms are relevant and if they need to be shown to the operator.

TecOS ALERT manages the alarms in real time and works on a layer above the plant's DCS, reading the DCS alarms (read only; no write permissions). The results are displayed on a simple, intuitive interface oriented to reduce human error and whose design follows the criteria of Human Factors Engineering.

FAQs

The plant’s DCS must have connectivity via the OPC UA A&E communication protocol. If this is not available, other alternative communication protocols can be assessed.

You need a DCS or SCADA that allows to communicate alarm data to external systems.

List of alarms implemented.

Records of plant alarms that show all operating modes. The records must include at least 1 year of operation and, ideally, it should include 2 years.

Process data records for the same period as the alarm period provided.

Blog News

Our world is changing at an unprecedented speed, involving challenges such as the population growth, the environmental degradation and the economic re…

The digital copy that enhances and improves the performance of the reality being replicated.

The term "digital twin" seems to be a magic concept in th…

The power generation industry is currently facing the need to reduce operating costs while maintaining the safety and availability of power plants. Co…